Condition:

New

Type:

Reflow Solder

Applicable Industries:

Garment Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use

Showroom Location:

Canada, Turkey, United Kingdom, Italy, France, Germany, Brazil, Peru, India, Russia, Morocco, Argentina, Colombia

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

2 years

Core Components:

PLC, Bearing, Pump

Usage:

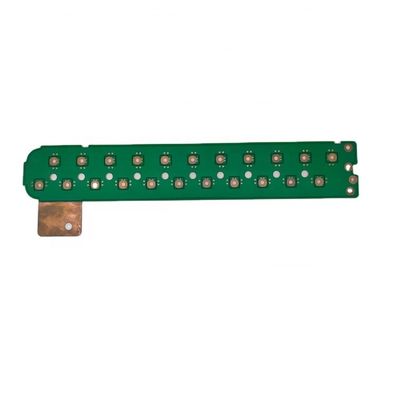

PCB Soldering

Voltage:

380V

Dimensions:

3800*1100*1490mm

Rated Duty Cycle:

100%

Rated Capacity:

3KW

Current:

50/60Mhz

Warranty:

1 Year, 1 Year

Key Selling Points:

Low Maintenance Cost

Weight (KG):

1 KG

Weight:

900kg

Name:

reflow soldering oven

Function:

PCB soldering

Heating zones:

up bottom 6

cooling zones:

up bottom 1

Temperature range:

Room Temperature ~ 300

Heating Zone Length:

2500mm

Heating type:

hot air

Rail width max:

300mm

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Canada, Turkey, Italy, France, Germany, Brazil, Peru, India, Russia, Japan

After-sales Service Provided:

Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

인증:

CE ISO

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!